What are the connection methods for aluminium composite panels

There is also a plastic welding method, but only for PE core material, using an electrically heated torch, which melts the aluminium sheet with heated air, and the polyethylene core material layer and the polyethylene plastic welding rod are joined after cooling.

With competitive price and timely delivery, Ding’ao sincerely hope to be your supplier and partner.

There are many different ways to connect wholesale aluminium composite panels if they need to be connected in an application, let's look at them specifically.

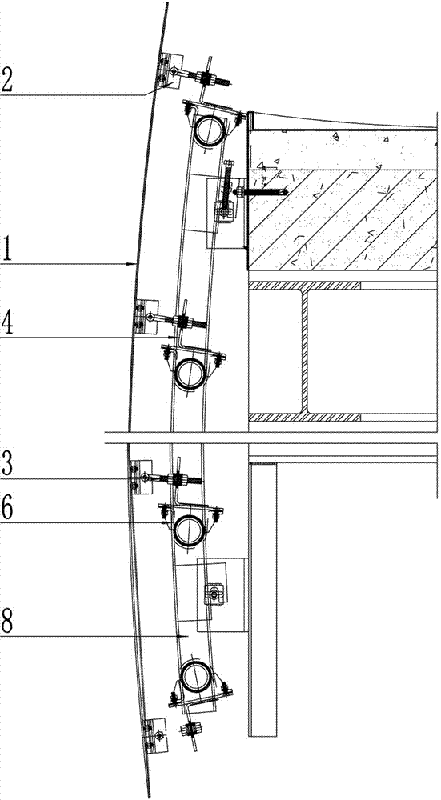

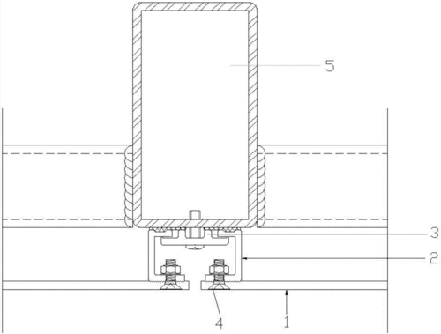

One method is the rivet connection method, which is the use of rivets suitable for aluminium to connect between panels or between panels and other materials. For applications outdoors or in areas of high humidity, stainless steel core rivets should be used to avoid rusting affecting the panel surface of the aluminium composite panel. When using threaded fixings outdoors, the thermal expansion coefficient of the aluminium composite panel needs to be taken into account. To avoid bending of the aluminium composite, the use of stainless steel screw patterns with sealing washers will prevent the aluminium composite panel from being extruded and deformed. It is also possible to use a combination of clamps to fix and connect aluminium composite panels. The clamps can be made from seemingly aluminium or plastic materials and are generally made up of two parts and connected by screws.

There is also a plastic welding method, but only for PE core material, using an electrically heated torch, which melts the aluminium sheet with heated air, and the polyethylene core material layer and the polyethylene plastic welding rod are joined after cooling.

Contact us to discuss your requirements of Redispersible latex powder. Our experienced sales team can help you identify the options that best suit your needs.